Learning the technology of PLC programming is not as difficult as you think - ten sword practices

post time:2024-03-30 16:59:25 author:Free Little Bird clicks:1885 【 Size:big middle small 】

Learning to master PLC programming is not as difficult as you think. But there are still many friends who want to learn and want to get started, and these friends can be roughly summarized into two types, one is how beginners can get started quickly, and the other is that I write about pediatrics, can you introduce something tall?

In the process of learning a skill, there are two most difficult time periods, I don't know how to learn before I get started, and I don't know how to improve quickly after I get started. On the contrary, when the technology is raised to a level, it can be integrated, and it is not so difficult to see anything.

Just like a martial arts master, when he practiced swordsmanship when he was young, he always wanted his sword to be extremely sharp and indestructible. After accumulating, the heavy sword has no edge, is not skillful, and it is rampant all over the world. When gradually entering the realm of transformation, it does not stagnate in things, and plants, bamboo, and stones can be used as swords.

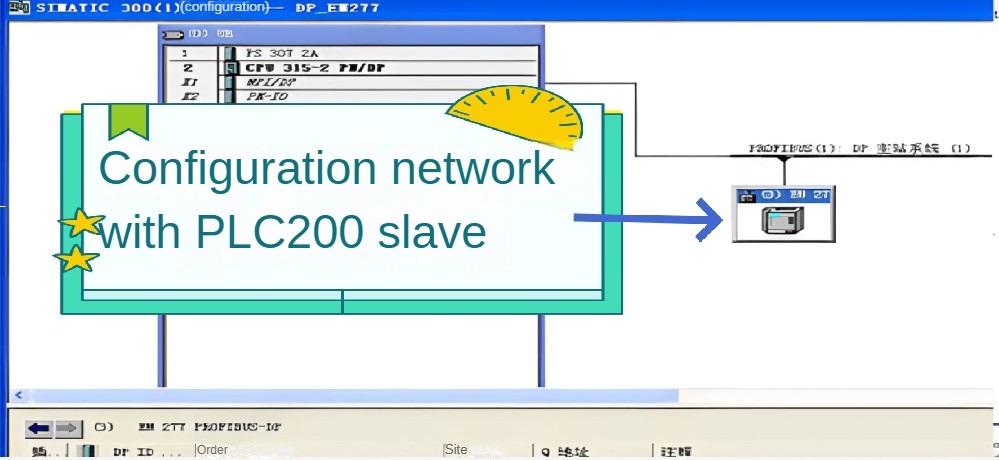

Introduction to Siemens PLC programming

If you are the second category I wrote above, I would like to say that when you learn anything unfamiliar, you don't feel pressured and have your own methodology. Then congratulations, you have reached the realm of no sword and better than a sword. If you haven't started yet, or have a certain foundation, but don't know how to go further. I hope that after reading my article, it can be of some help to you.

In this era of rapid change, it is becoming more and more important to learn whether you can quickly get started with any technology. In the face of unfamiliar knowledge in work and life, the ability to learn quickly is becoming more and more important.

Quickly master PLC technology, see if the following 9 suggestions are helpful to you:

1. Whether you are interested or not is actually not that important, adults need to solve many problems, whether it is work or study, it is most effective to drive with tasks. This is also why people with more pressure in their jobs can quickly master PLC skills, while no matter how much time you give you in school, you may not be able to learn much. 2. The basics are important, but you don't have to start from the basics. Learning PLC from the basics at work is a misunderstanding of many people. It is recommended to go straight to the project, what problems need to be solved, master the corresponding knowledge, learn the basics when encountering the basics, and master the theory when encountering the theory. Only with specific and clear goals can we get twice the result with half the effort. (Not that the foundation is not important)

To give you my own example, I have been learning English recently, and instead of memorizing words like before, I directly found the technical manuals that needed to be read, translated little by little, looked up the dictionary when I encountered something I didn't understand, and marked the words I didn't understand in the blanks. After reading it, I can at least understand most of the manual, regardless of English. After reading a complete English material, it is impossible to say that English has not improved at all.

On the contrary, starting from memorizing words and looking up syntax as before, after learning to master PLC programming for a year and a half, you may not have the ability to practice and read a technical manual.

3. Learn to imitate, it is difficult for beginners to master PLC very comprehensively, when encountering problems, you can see how others program it, or just use it. In the process of use, it is slowly modified according to the requirements of the project. Constant imitation, coupled with a lot of deliberate practice, can lead to progress. In addition to programming, drawing schematics is the same, directly referring to the mature drawings of predecessors, which is far more efficient than exploring by yourself.

4. Advanced learning should start from the structure, the few just said, are all ways to solve specific problems, when entering the industry for a period of time, feel that there is no way to progress, to start from the overall structure, at this time, through the surface, dismantle the underlying logic, learn to grasp the essence and find the law. You can try to find this textbook, from PLC principle, switching processing, analog processing, communication, PID, servo control... Combined with work experience, sort out each piece from scratch.

5. Compare more, find patterns, and master the knowledge points of Siemens S7-200, you can learn S7-300 through comparison. Find out the different places, grasp the essential things, grasp the different points, and understand the essential principles at a deep level. Similarly, is it still difficult to learn from Siemens PLC and then do projects with Mitsubishi and ABB?

6. Learn to disassemble the goal, break the goal, and break through each part one by one. Learning in this way is more effective than taking care of the overall situation in the first place. For example, if you only learn free oral communication in a period of time until you fully master it, it is more efficient than learning it again every time you use it.

Siemens PLC Learning (200 series)

7. Learn to use fragmented time, don't underestimate fragmented time, now our time is highly fragmented, it is difficult for you to take out a day to read and study. Use fragmented time to think about specific knowledge points and reflect on your recent learning effects. A lot of learning integration is done inadvertently.

8. Ask "famous teachers", not those friends who you think his skills are okay. Professional people can point out the shortcomings in your direction and logical loopholes, so that you can avoid detours. The law of sociology tells us that the average ability of friends around us can basically represent your ability, so you can discuss more with your friends, but it is better to ask experts for advice, maybe the mistakes you make now, he has found a solution back then.

9. Manufacturing feedback, when programming, we need to convert the logic into a program, and then verify it through PLC. This can prove that your logic is true, and the learning process is the same, learning is input, mastery is logical processing, and problem- solving ability is output. With output, there is feedback, and we can know the learning situation for a period of time. There are ways to create feedback, such as telling others, writing down the results of thinking, and programming logical reasoning to verify.

The best time to plant a tree was 20 years ago, and the best time to learn to master PLC programming is now. It's never too late to learn a skill, and mastering a skill is like having an extra weapon that can make your life hang up. Let's start acting now!

Guess you like

Application and development of PLC technology in smart home

2489

2489

What is PLC and how does it work? -Understanding PLC

2713

2713

How does the PLCjudge the fault through the fault indicator of the CPU?

2322

2322

What is the meaning of the CPU mode selector switch in PLC?

2048

2048

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

2076

2076

Retentive on-delay timer of five commonly used PLC timers (4)

1627

1627

At the critical moment, he walked away again

Application and development of PLC technology in smart home

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

Bearings play an important role in improving the power of new energy vehicles

Gear reducer analysis introduction

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

New energy vehicle reducer

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

(2) 1 - Xiao Zhang was blocked

(2) 1 - Xiao Zhang was blocked

Five commonly used PLC timers on-delay timer (3)

Bearings play an important role in improving the power of new energy vehicles

How does the PLC-200 series communicate with the PLC-300 series CPU?

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

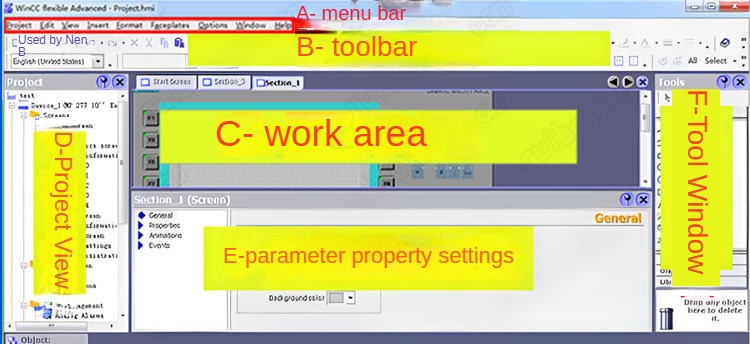

How to edit the touch screen interface corresponding to PLC?

Learning the technology of PLC programming is not as difficult as you think - ten sword practices

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

Learn PLC programming from scratch

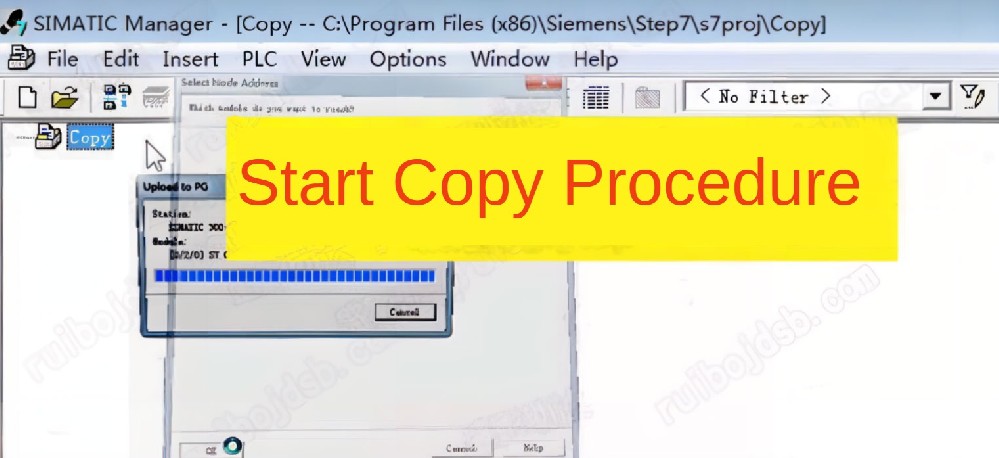

How to view other people's PLC programs in the machine and copy them to the computer?

What is PLC and how does it work? -Understanding PLC

Application and development of PLC technology in smart home

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

Gear reducer analysis introduction

How does the PLCjudge the fault through the fault indicator of the CPU?

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

What is the meaning of the CPU mode selector switch in PLC?

New energy vehicle reducer

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

X

X