Gear reducer analysis introduction

post time:2024-04-12 17:05:01 author:Free Little Bird clicks:2359 【 Size:big middle small 】

Gear reducer is a common mechanical transmission device widely used in various industrial fields. It realizes the reduction of motor output speed and the increase of torque through the meshing transmission of gears, so as to meet the different needs of mechanical equipment for speed and torque. This article will provide an in-depth analysis and introduction to gear reducers, including their working principles, structural characteristics, classification and applications.

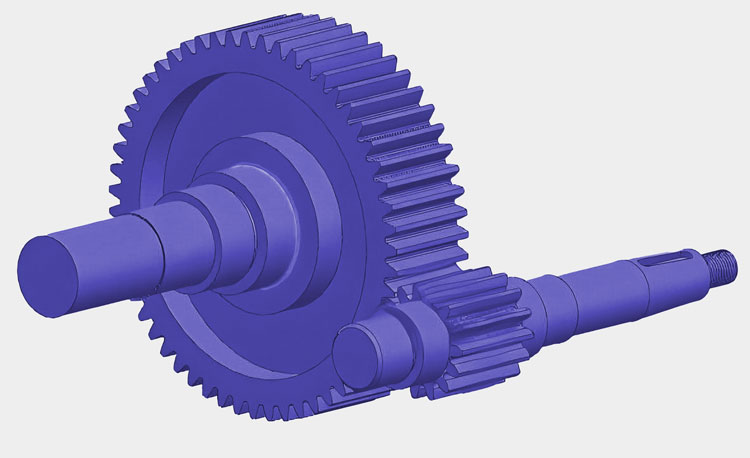

Single-stage gear reduction

1. Working principle

The working principle of a gear reducer is based on the mechanics of gear transmission. When the active gear rotates, the driven gear rotates through the meshing action of the gear. Due to the different number of gear teeth, there will be a certain proportional relationship between the speed of the driving gear and the driven gear, so as to achieve the effect of deceleration. At the same time, due to the large meshing area of the gear, the transmission efficiency is high, and it can withstand large torque and load.

2. Structural characteristics

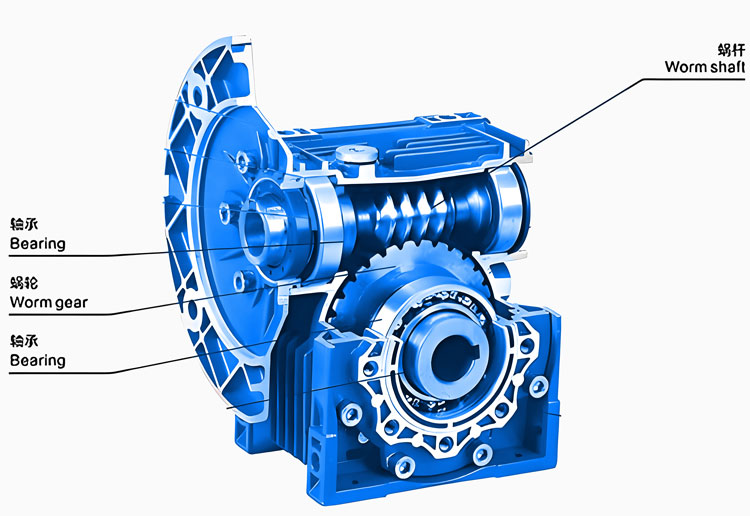

Gear reducers are usually composed of parts, such as boxes, gears, bearings, and oil seals. Among them, the box is the shell of the reducer, which is used to support and fix the internal parts; Gears are the core components that achieve reduction transmission, usually made of high-strength materials to ensure their wear resistance and durability; bearings are used to support the rotation of gears, reducing friction and wear; The oil seal is used to prevent lubricating oil leakage and ensure the normal operation of the reducer.

3. Classification

According to the different structures and characteristics of gear reducers, they can be divided into the following categories:

Single-stage gear reducer: It has the characteristics of simple structure, small size, and light weight, and is suitable for occasions where the reduction ratio and torque requirements are not high.

Multi-stage gear reducer: Through the series or parallel connection of multiple gears, it achieves a larger reduction ratio and higher torque output, suitable for occasions with high requirements for transmission performance.

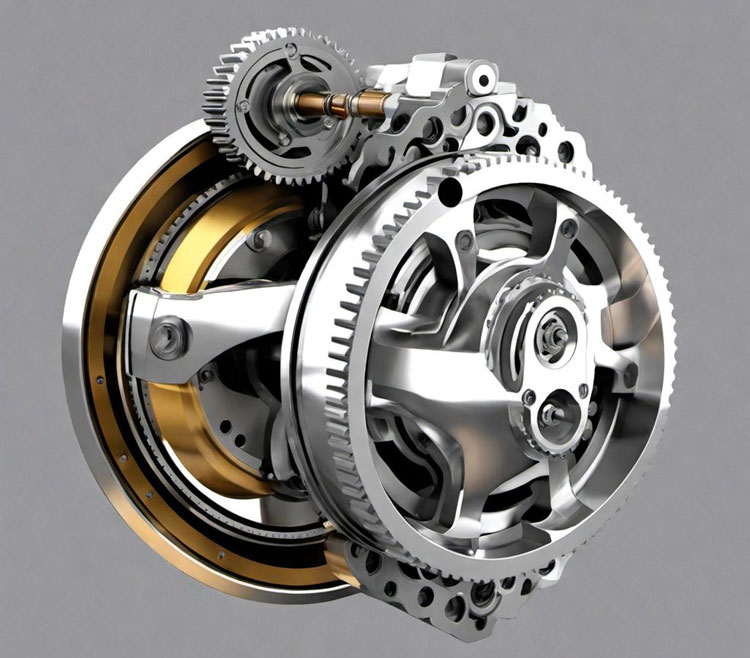

Planetary gear reducer: adopts planetary gear train structure, with compact structure, stable transmission, large bearing capacity and other characteristics, and is widely used in high-precision and high-reliability transmission systems.

4. Application

Gear reducers are widely used in various industrial equipment, such as cranes, excavators, conveyors and other heavy machinery and equipment, as well as light industrial equipment such as machine tools, fans, and pumps. In these equipment, gear reducers play a key role in reducing rotational speed and increasing torque, ensuring the normal operation and production efficiency of the equipment.

In addition, with the continuous development of industrial automation, gear reducers are becoming more and more widely used in robots, automation equipment and other fields. They provide reliable support for the automated operation of equipment through precise transmission and control.

5. Maintenance and upkeep

The normal operation of the gear reducer is inseparable from regular maintenance and servicing. During use, the amount and quality of lubricating oil should be regularly checked, and the lubricating oil should be replaced or replenished in time to ensure the normal operation of the reducer. At the same time, attention should also be paid to checking the wear of gears, bearings and other components of the reducer, and replacing severely worn components in time to extend the service life of the reducer.

6. Development trend

With the continuous advancement of science and technology and the rapid development of industry, gear reducers are constantly innovating and improving in terms of performance, structure, and materials. In the future, gear reducers will pay more attention to the improvement of transmission efficiency, load-bearing capacity and reliability, and at the same time, they will also pay more attention to environmental protection and energy conservation requirements to adapt to changing market demands.

To sum up, gear reducers, as an important mechanical transmission device, play a pivotal role in industrial production. Through an in-depth understanding of its working principle, structural characteristics, classification and application, we can better select and use gear reducers to provide a strong guarantee for the normal operation and production efficiency of equipment.

Guess you like

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

2411

2411

Bearings play an important role in improving the power of new energy vehicles

1799

1799

Gear reducer analysis introduction

2360

2360

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

2238

2238

New energy vehicle reducer

2014

2014

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

1996

1996

At the critical moment, he walked away again

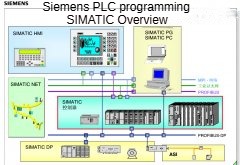

Application and development of PLC technology in smart home

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

Bearings play an important role in improving the power of new energy vehicles

Gear reducer analysis introduction

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

New energy vehicle reducer

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

(2) 1 - Xiao Zhang was blocked

(1) Is there a "deceive" in the so-called "master"?

What is the content of PLC programming learning, is it difficult?

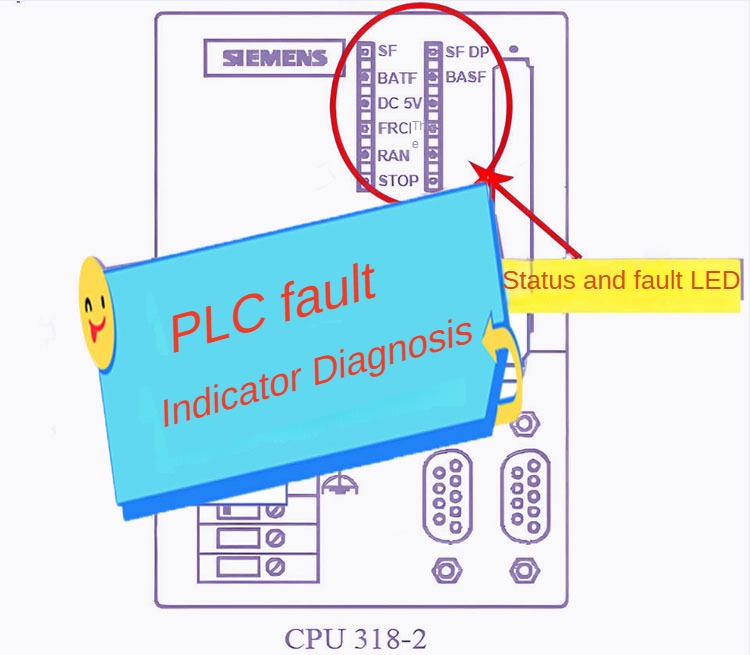

How does the PLCjudge the fault through the fault indicator of the CPU?

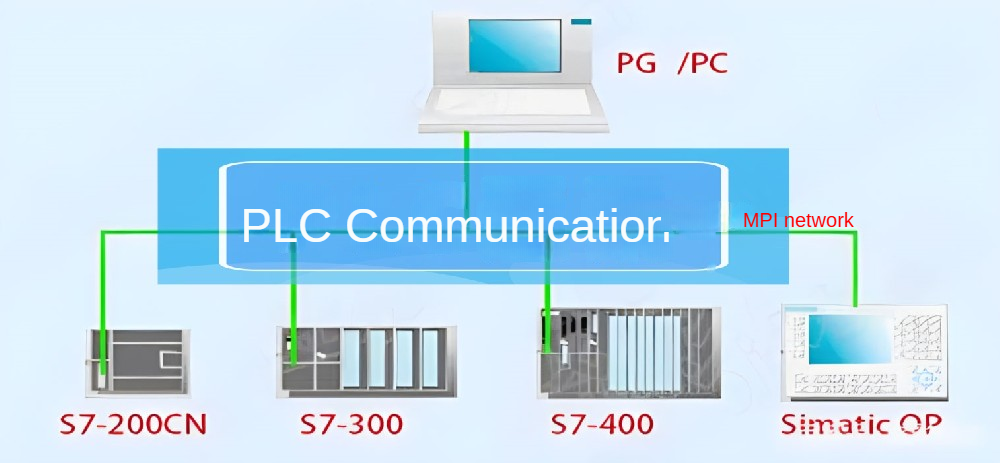

What are the communication methods of CPU200CN series PLCs?

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

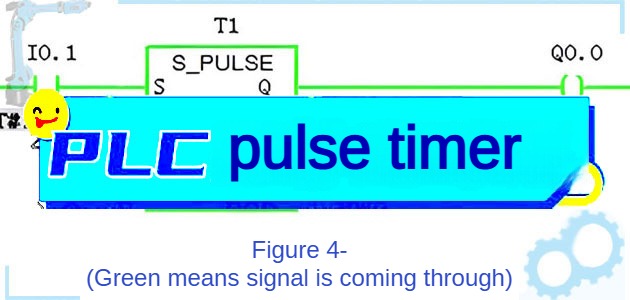

Five commonly used PLC timers-Pulse Timer (1)

What is the data structure in PLC programming?

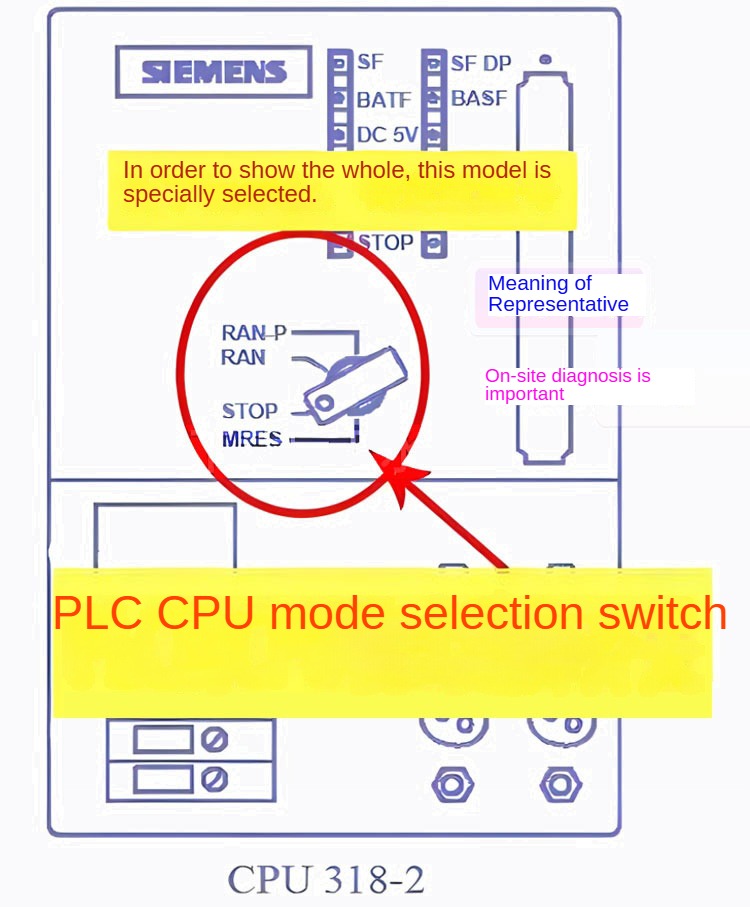

What is the meaning of the CPU mode selector switch in PLC?

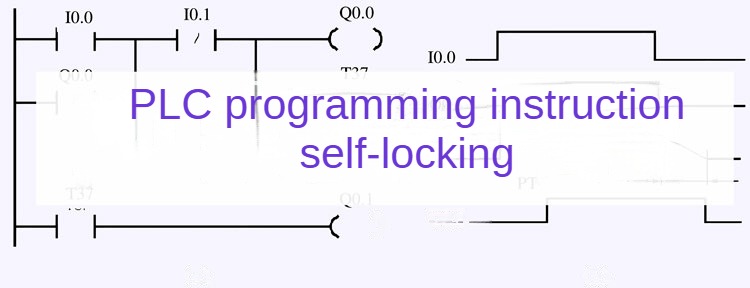

PLC programming instructions are self-locking

What is PLC and how does it work? -Understanding PLC

Application and development of PLC technology in smart home

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

Gear reducer analysis introduction

How does the PLCjudge the fault through the fault indicator of the CPU?

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

What is the meaning of the CPU mode selector switch in PLC?

New energy vehicle reducer

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

X

X