Mechanical and electrical equipment maintenance-observing smelling Questions touching

post time:2024-04-09 17:50:56 author:Free Little Bird clicks:1387 【 Size:big middle small 】

Mechanical and electrical maintenance of equipment(looking listening Questions touching) - that is, it is equivalent to seeing a doctor for equipment, people will get sick if they eat grains for a long time, and the same is true for equipment, and the equipment will also get sick and paralyzed after a long time of use. Then we have to prevent it before we get sick, which is called overhaul in terms of equipment.

Equipment mechanical and electrical maintenance is equivalent to seeing a doctor for equipment, people will get sick if they eat grains for a long time, and the same is true for equipment, and the equipment will also get sick and paralyzed after a long time of use. Then we have to prevent it before we get sick, which is called overhaul in terms of equipment, which is actually a truth. The following is a discussion with you about the method of "looking, hearing, asking, and cuttingn used in maintenance.

Many faults in equipment maintenance can be detected and prevented in advance. Among them, daily maintenance and spot inspection is one of our commonly used methods, in which for equipment failure, we can imitate the traditional Chinese medicine doctor's "look, smell, ask, and cut" method of seeing a doctor, detect the condition (equipment failure) in advance, study how to solve it in advance, give us an advance amount in time, and keep the equipment in good working condition. So today I will take you to understand the mechanical and electrical equipment industry.

I. The "observing" of equipment maintenance and inspection methods

"observing" - as the name suggests, it is watching, and observing is the simplest, most basic and most important inspection method in equipment point inspection. After a wait-and-see inspection, most equipment problems can be exposed and resolved, such as corrosion, damage, and detachment of parts. loosening of the connecting screws of each part; Abnormal display of various indicator instruments and meters can detect equipment defects and solve them in time. However, it is best to carry out this process in an orderly manner according to a certain order and method, and not to walk and look blindly and disorderly, without a goal. It is thought that the general production equipment is relatively large or composed of several parts, which cannot be seen at a glance, and the parts that need to be inspected are also scattered in different places of the equipment. Therefore, only in accordance with a certain order of spot inspection will there be no missed inspections. The order of observation can be as follows: 1) According to the composition of the equipment. For example, check in the order of prime mover mechanism, transmission mechanism, actuator mechanism, etc.; 2) By category of equipment. For example, check in the order of mechanical parts, electrical parts, hydraulic parts, etc.; 3) Proceed according to the orientation of the equipment. That is, from front to back, from bottom to top, from outside to inside, etc. According to this order, problems existing on the outside of the equipment, such as the running and dripping of water, wind, oil and gas, corrosion, damage and detachment of parts, loosening of link screws in various parts, abnormal display of various indicator instruments, and various friction pairs, chains, rods and boxes can generally be found and solved.

2. "Smell" of equipment and mechanical electrical maintenance inspection methods

"Smell" - to listen to the sound and smell: suitable for inspection and diagnosis of internal faults of equipment and leakage of flammable and explosive gases. various motor and electrical component coils are burned; Leaks in combustible gas pipelines such as gas and natural gas are not visible from the outside, but they can produce abnormal sounds or odors, whether large or small. Through these sounds and smells, we can find the problem along the way. If it is overheated, short-circuited, or faulty, it may smell burning, smoke, and volatile odors of plastic, rubber, paint, lubricating oil, etc.

3. "Questions" about equipment maintenance and inspection methods

"Ask" - is to inquire about the equipment operators and listen to their equipment hidden dangers and fault reports. Especially in the early stage of equipment failure, when the appearance is not obvious, our maintenance personnel may not notice it, but they may have noticed it. If this information can be obtained in time, it can not only reduce equipment maintenance costs, but also avoid larger equipment accidents, so as to prevent problems before they occur. The advantage of "ask" is that it narrows down the fault target, or even directly locks the target, which provides convenience for us to quickly and accurately find and solve problems.

4. " touching" of equipment maintenance and inspection methods

" touching" - is to touch the inspection part of the device with your hand to sense the temperature of its surface. We know that the heat generation of the equipment is very Iow when working normally, and the surface temperature generally does not exceed 600C. However, when the equipment is overloaded or the lubrication conditions are not good, it may cause serious consequences such as deformation, wear and even rupture of internal components. After these parts are damaged, the frictional resistance generated during operation will be greatly increased, and the heat generated by friction can make the temperature of the shell of the body rise significantly, higher than the normal temperature, which can be felt by touching it with your hands.

Mechanical and electrical equipment maintenance inspection is a key step in preventive maintenance, it is the key to early elimination and prevention of equipment diseases, and it should attract our sufficient attention.

Guess you like

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

1833

1833

(1) Is there a "deceive" in the so-called "master"?

1400

1400

Mechanical and electrical equipment maintenance-observing smelling Questions touching

1388

1388

(2) 1 - Xiao Zhang was blocked

1778

1778

(2) At the critical moment, Xiao Zhang was taken away

1783

1783

At the critical moment, he walked away again

26

26

At the critical moment, he walked away again

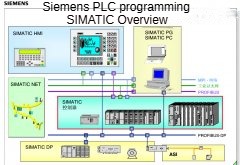

Application and development of PLC technology in smart home

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

Bearings play an important role in improving the power of new energy vehicles

Gear reducer analysis introduction

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

New energy vehicle reducer

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

(2) 1 - Xiao Zhang was blocked

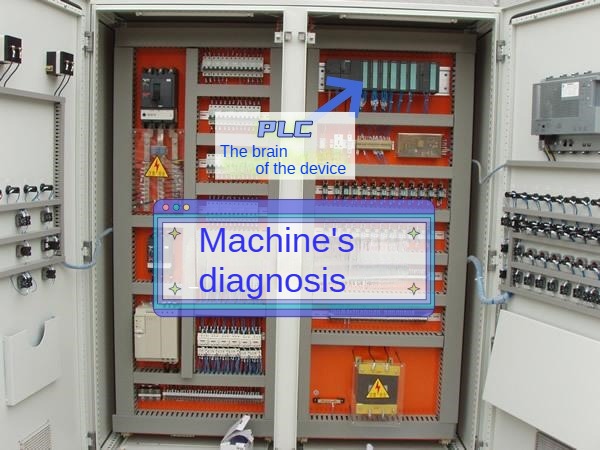

What is PLC and how does it work? -Understanding PLC

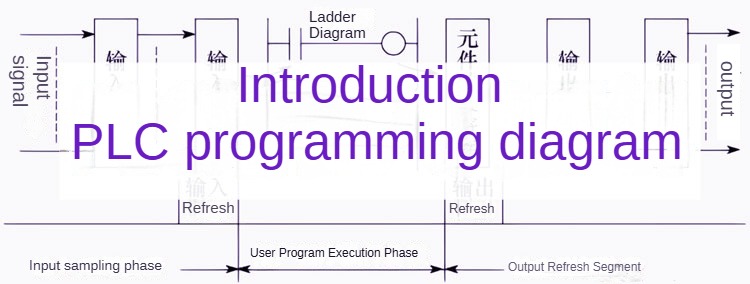

PLC programming introductory illustration

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

Gear reducer analysis introduction

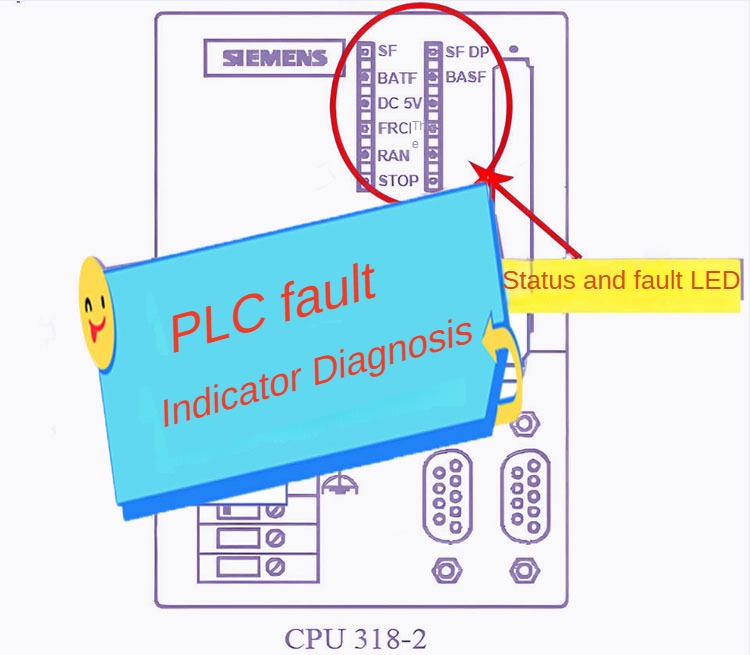

How does the PLCjudge the fault through the fault indicator of the CPU?

Mechanical and electrical equipment maintenance-observing smelling Questions touching

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

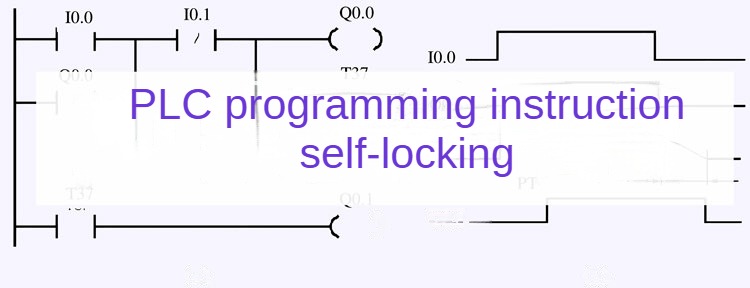

PLC programming instructions are self-locking

What is the content of PLC programming learning, is it difficult?

At the critical moment, he walked away again

What is PLC and how does it work? -Understanding PLC

Application and development of PLC technology in smart home

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

Gear reducer analysis introduction

How does the PLCjudge the fault through the fault indicator of the CPU?

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

What is the meaning of the CPU mode selector switch in PLC?

New energy vehicle reducer

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

X

X