What is the content of PLC programming learning, is it difficult?

post time:2024-03-31 14:06:20 author:Free Little Bird clicks:1569 【 Size:big middle small 】

Many people are passionate about Siemens PLC programming, but they don't know how to start, in response to this situation, teachers specially arrange Siemens PLC training courses,and all students who participate in the training provide technical support for students for a long time.

Training objects:

1. For those who have a strong interest in PLC and want to master a skill through learning,and then want to engage in one aspect of work in this area.

2. Front-line electrical engineering and technical personnel for the majority of enterprises.

3. For the relevant automation industry authorities, departments, scientific research institutions, teachers of relevant colleges and universities, engineering projects and sales personnel of relevant automation companies.

4. For engineering students who graduated from colleges and secondary schools, they can enter the workplace after studying and be able to quickly work in the core control position of automation.

Training objectives: (to achieve maintenance, transformation, and independent creation and design project programming):

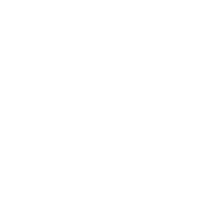

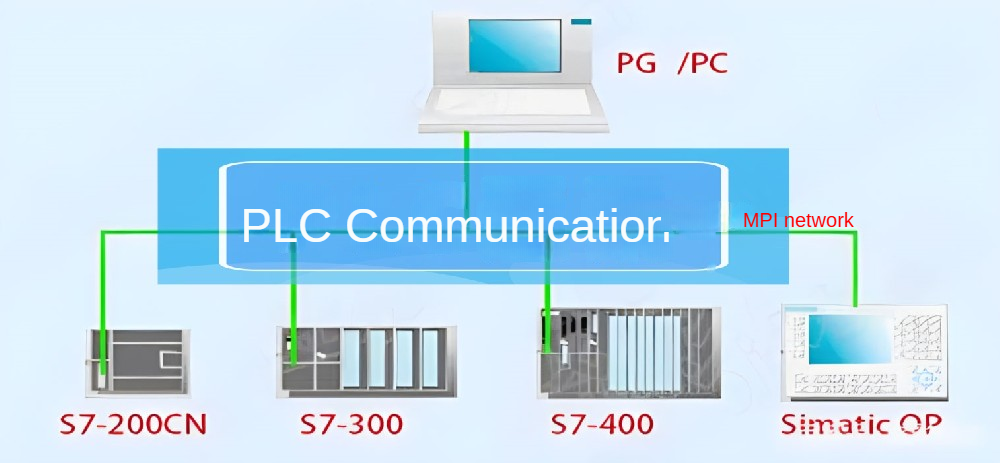

1. Familiar with the parameter settings of CPU, 1/0 module, MPl network, DP network, and Ethernet network. The comprehensive system of the software is used for parameter setting.

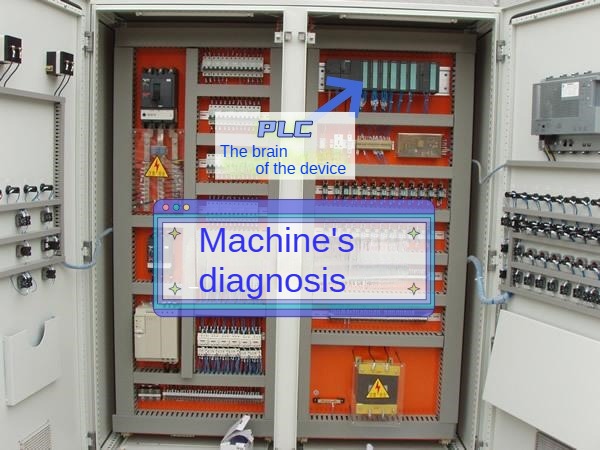

2. Through the powerful diagnosis function of the software itself, it can flexibly grasp and deal with all faults caused by software and hardware on site. In this way, it can achieve the ability to comprehensively cope with common fault handling problems on site.

3. It can carry out automatic engineering transformation of the existing production line.

4. Be able to independently create engineering projects of medium difficulty (linear programming, structured programming, creating FB, FC, DB and other program blocks).

5. Understand analog operation, familiar with analog PID automatic control and programming of constant temperature, flow, liquid level and pressure.

6. Be familiar with the basic programming skills of PLC ladder charts

7. According to the students' own knowledge background, learn and master PLC statement table programming to a certain extent.

Conditions for participating in training:

1. Students take a basic knowledge test before learning to see if they meet the conditions for learning PLC.

2. Trainees participating in the training should have certain basic knowledge of electrical appliances or have one to two years of practical experience as an electrician, and understand the basic principles of electrical control.

3. Be able to operate a computer.

4. Before training, it is best to read the electrical control book, be familiar with the basic knowledge of PLC, and have a certain understanding of the training-related knowledge, or list the problems you do not understand, so that the training effect with problems will be better.

5. Before participating in the training, it is best to communicate with our training engineers and make preparations before training. Have a simple psychological and intellectual preparation to avoid the blindness of learning.

6. Training form:

a. Pay attention to the cultivation of theoretical knowledge and hands-on operation ability, in the classroom students (one machine per person) and the teacher through computer projection synchronous interactive learning, in the morning lecture on the use of software, in the afternoon on engineering cases require each student to operate on the computer and download to PLC debugging to ensure the learning quality of students, one period of learning will not be free of charge in the next period.

b. Siemens PLC training engineers are senior automation engineers with more than 20 years of experience in field engineering and fault handling, rich theoretical foundation, and 12 years of experience in inverter PLC training, and senior engineers who are lecturers in Siemens PLC training courses.

7. Training content:

PLC module characteristics, hardware structure, installation, wiring, maintenance and maintenance methods, etc. (the whole training is explained in kind).

Wiring characteristics and precautions of DI/DO, AI/AO modules of PLC (mainly explain the wiring method of connecting various instrument sensors to PLC modules and the wiring methods of modules connected to various field actuators).

The types and methods of addressing the DI/DO, AI/AO modules of PLC, and the analog and digital addressing methods of the extended rack are introduced (using software online configuration teaching, so that students can operate the configuration process by themselves, so that abstract concepts can be easily realized by physical objects).

Parameter setting methods and precautions for DI/DO, AI/AO modules of PLC (Compared with the physical module and PLC configuration software, the instructor completes the software and hardware parameter settings of the module step by step.)

STEP 7 Software installation points, precautions, setting points of common software parameters, and software application methods (each student is required to complete the installation and setting of the software by himself, and use practical operations instead of abstract teachings).

MPl interface settings, DP interface settings, PG/PC interface communication settings, etc. (each student is required to operate the settings online in person).

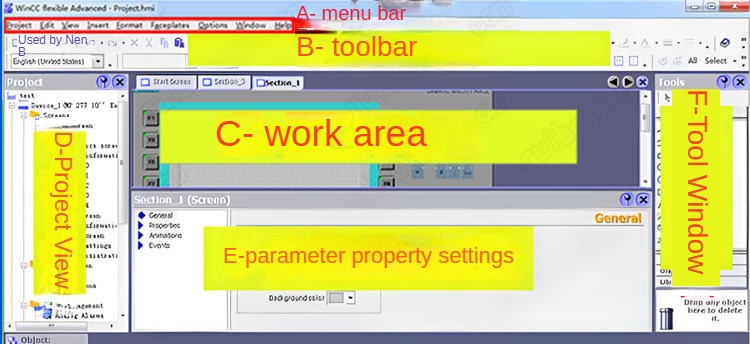

STEP 7 Software programming method: Focus on the project formation method, site insertion method, hardware configuration method, symbol table editing method, forced variable debugging method, variable monitoring table creation method, and master the software programming method step by step through case projects (each student is required to operate the settings online).

STEP7 Introduction to programming methods: focus on learning linear programming and structured programming, and focus on the steps and precautions of creating FB, FC, and DB shared data blocks and DB background data blocks; How to call the call methods of FB, FC, SFB, SFC and other blocks in OBI (each student is required to operate the settings online).

It handles analog operations and programs the analog to automatically control the constant temperature, flow, liquid level, and pressure.

STEP 7 Hardware configuration method, focusing on the hardware configuration of STEP7- 300, hardware configuration of STEP7-400, configuration of expansion rack, MPl network, and DP network (each student is required to operate the settings online). STEP 7 Online fault diagnosis of hardware. How to find hardware fault points through online diagnosis (each student is required to operate the settings online).

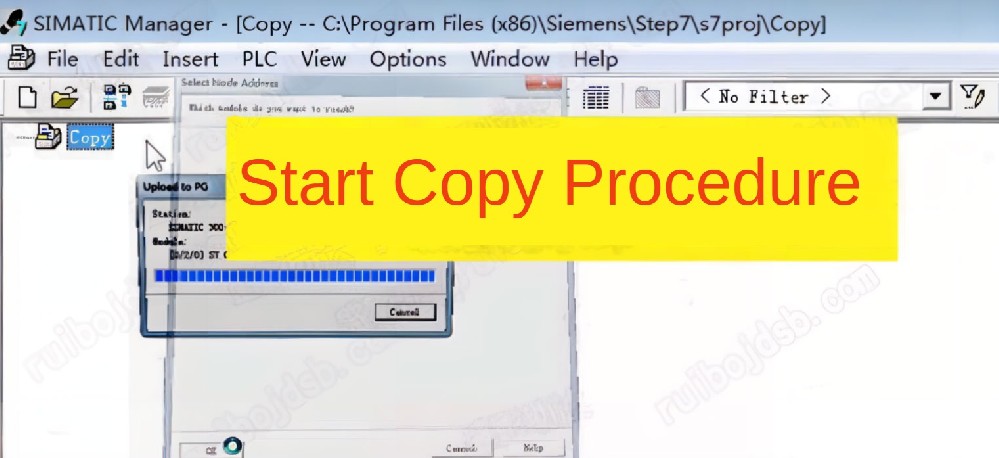

STEP 7 Online debugging of programs: online connection, program upload and download, online monitoring, coercion, method of finding program faults through CPU fault diagnosis buffer, finding and troubleshooting common faults, and online testing of self-written programs (each student is required to operate the settings online).

STEP 7 PLCSIM simulation software installation and setting method, software application method (each student is required to operate the settings online).

S7-300/400 Communication and Network Configuration. Focus on explaining MPl network, DP network, ET200M field workstation configuration, Ethernet communication, etc. (the training is all physical operation, and each student is required to operate the settings online).

The above Siemens PLC training content will be appropriately adjusted according to the actual teaching content and teaching method according to the students' own basic situation (such as knowledge acceptance).

Guess you like

Application and development of PLC technology in smart home

2489

2489

What is PLC and how does it work? -Understanding PLC

2713

2713

How does the PLCjudge the fault through the fault indicator of the CPU?

2322

2322

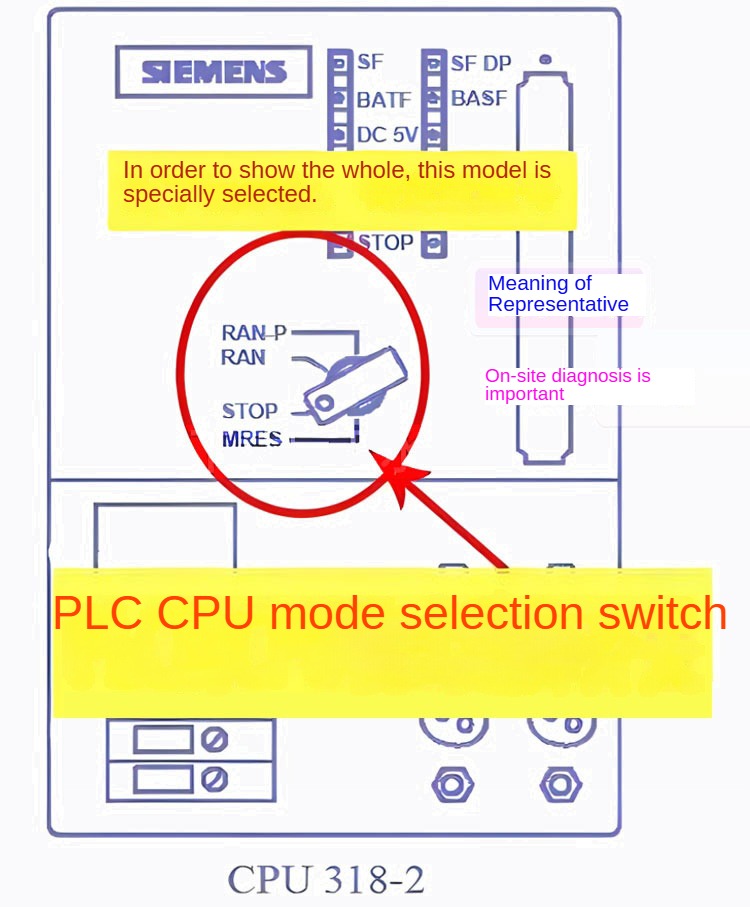

What is the meaning of the CPU mode selector switch in PLC?

2048

2048

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

2075

2075

Retentive on-delay timer of five commonly used PLC timers (4)

1627

1627

At the critical moment, he walked away again

Application and development of PLC technology in smart home

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

Bearings play an important role in improving the power of new energy vehicles

Gear reducer analysis introduction

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

New energy vehicle reducer

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

(2) 1 - Xiao Zhang was blocked

What are the communication methods of CPU200CN series PLCs?

What is the meaning of the CPU mode selector switch in PLC?

New energy vehicle reducer

(2) At the critical moment, Xiao Zhang was taken away

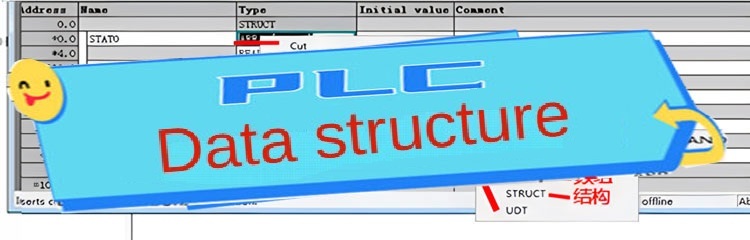

What is the data structure in PLC programming?

(2)2-Xiao Zhang accepted a bribe - twists and turns and lessons

How to view other people's PLC programs in the machine and copy them to the computer?

Mechanical and electrical equipment maintenance-observing smelling Questions touching

Bearings play an important role in improving the power of new energy vehicles

How to edit the touch screen interface corresponding to PLC?

What is PLC and how does it work? -Understanding PLC

Application and development of PLC technology in smart home

Planetary gears for new energy vehicles: a key technology to improve power transmission efficiency

Gear reducer analysis introduction

How does the PLCjudge the fault through the fault indicator of the CPU?

New energy vehicle planetary reducer: the advantages are highlighted, leading the future transmission technology

Five commonly used PLC timers to comb out the Off-Delay Timer (5)

What is the meaning of the CPU mode selector switch in PLC?

New energy vehicle reducer

The role of relays in new energy vehicles: a comparison with traditional fuel vehicles

X

X